Imitation glass (plexi or pvc)

OMSCHRIJVING

De ‘Window Liners’ zijn de raamkozijnen (raamomlijstingen) die men kan vinden tegen de verschillende raamframes.

Je kan ze kant-en-klaar kopen bij sommige firma’s die cockpit stuff verkopen. Algemeen zijn ze erg prijzig en ze moeten ook net passen met het window frame dat men gebruikt.

Het is dan ook de bedoeling mijn ‘Window Liners’ zelf te maken.

De ‘Window Liners’ zijn onderverdeeld in :

- Middle strut windshield window liner;

- Side window armrest/Chart holder (Capt en F/O);

- AFT Lower window liners (Capt en F/O);

- AFT Upper/Middle window liners (Capt en F/O);

- FWD Upper/Front window liners (Capt en F/O);

- Imitation glass (plexi or pvc).

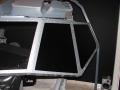

PLEXIGLAS IN DE WINDOW FRAMES

De window frames van de voorste ramen (windshield) en de zijramen zijn opgevuld met plexiglas van 4 mm dikte. De gangbare dikte die door verschillende cockpitbouwers worden gebruikt varieert van 2 tot 4 mm. 2mm is misschien iets te dun en 4 mm is misschien iets te dik. Een dikte van 4 mm is wel steviger maar moeilijker om te plooien.

Het plexiglas heb ik gekocht bij Benvitec in Beringen (B). Niet ver van mijn thuisadres en dus zelf gaan bestellen en afhalen.

Een ander adres is bv. Bouwplastics.nl.

Het plexiglas is aan beide zijden bekleed met beschermfolie en dit tegen krassen of eventuele kleine beschadigingen.

Toch geef ik het advies het oppervlak goed te controleren bij levering. In het bedrijf waar je het koopt kunnen ze nogal ruw omspringen met die dingen (het zou normaal niet mogen) maar bij mij heb ik toch een paar krassen ontdekt.

Helaas zie je dit enkel wanneer je de beschermfolie aan beide zijden verwijderd hebt. Dus in principe te laat …

Ik heb dit kunststofglas op maat laten zagen d.w.z. op de juiste lengte en breedte. 2 rechthoekige stukken voor de voorste ramen en 2 rechthoekige stukken voor de beide zijramen.

Om de juiste afmetingen te verkrijgen van de frameopeningen heb ik de binnenzijden van de window frames opgemeten in lengte en breedte en de hoeken met een hoekmeter.

Ik heb dan alle afmetingen in een juiste vorm afgetekend op de rechthoekige plexipanelen.

Zagen

Om te voorkomen dat de plexi gaat barsten tijdens het zagen heb ik de afgetekende lijnen overplakt met papieren schildertape en dit aan beide zijden. De plastieke beschermfolie doet hier ook al dienst voor maar een extra beveiliging kan geen kwaad. Plexi is nogal gevoelig voor barsten.

Het zagen zelf gebeurt met een gewone handzaag. Indien mogelijk een zaag gebruiken met kleine tandjes. Dit zaagt gemakkelijker, vooral om een begin te maken. Anders kan je eerst een begin maken met een ijzerzaag.

Het zagen kan je ook doen met een decoupeerzaag en dit met een zaagje geschikt voor kunststoffen en dus ook eentje met kleine tandjes.

Het zagen met een decoupeerzaag gebeurt sneller maar dan is het aan te raden het plexipaneel te fixeren tussen 2 planken om te voorkomen dat de plexi op en neer gaat bewegen tijdens het zagen. Risico op barsten ! Ook mag het zaagje niet te snel zagen. Risico op smelten van de plexi door het te warm worden van het zaagje bij een snelle zaagbeweging.

Om zeker te spelen heb ik dus het zaagwerk uitgevoerd met een gewone handzaag.

Het zagen gebeurt met het zaagblad zoveel mogelijk horizontaal. Veiliger tegen barsten en gaat gemakkelijker.

De hoeken en randen heb ik wat afgerond en gladgeschuurd met een vijl en schuurpapier.

Nadien is het natuurlijk noodzakelijk te controleren of de plexipanelen passen in de window frames.

Het probleem bij de FlyEngravity window frames is dat de buitenzijdes van de frames naar binnen staan. Je kan dus niet recht voorwaarts de plexi in de frames plaatsen. Er kom altijd een beetje plooiwerk bij te pas om dit te laten lukken.

Hierbij was het ook noodzakelijk enkele bouten los te draaien waarmee de window frames met elkaar waren verbonden.

Blinderen (tinten) van de zijramen met zwarte folie

Eénmaal dat het zaagwerk achter de rug is, heb ik de buitenzijde van de zijramen volledig laten beplakken (stickeren) met zwarte matte folie. Deze folie wordt ook gebruik bij het beplakken van auto’s.

Door de plexi te beplakken met zwarte folie ziet men aan de buitenzijde een zwart mat oppervlak en de binnenzijde, die dus niet beplakt is, geeft het effect van een zwart glasraam of het zicht van binnen naar buiten bij een nachtvlucht. Je ziet dus duidelijk dat er glas in de ramen zit zoals bij een echt vliegtuig.

Het buitenzicht is dus nihil maar dat is ook de bedoeling. Ik moet enkel de ‘outside view’ zien van de scenery en niet alle spulletjes die in de cockpitkamer staan.

Misschien later wanneer ik eventueel wil uitbreiden naar een 180°-view kan ik nog altijd de folie van de voorste zijramen verwijderen. Dat is geen enkel probleem.

De prijs van zwart plexiglas is opmerkelijk duurder dan gewoon glashelder en transparant plexiglas. Daarom heb ik gekozen om de ramen te laten stickeren met zwarte folie. Dit geeft hetzelfde effect. Ik had het geluk dit gratis te laten doen door iemand met ervaring.

Je kan deze klus ook zelf doen maar er is toch een beetje handigheid bij vereist. Het moet volledig vlak en strak uitgevoerd worden zonder dat er lucht onder de folie komt te zitten want elke klein luchtblaasje ziet men aan de binnenzijde.

Montage

Dan is het de beurt om de plexiramen in de window frames te monteren.

Het monteren gebeurt met boutjes van 10 mm lengte en 4 mm dikte.

Ik heb de plexi zijramen eerst voorlopig vastgezet met sergeanten (klemmen).

Voor de voorste ramen (windshield) was er geen plaats voor het gebruik van sergeanten. Hier heb ik dubbelzijdige tape gebruikt die ik aan de binnenzijde van de frames heb aangebracht.

Vervolgens heb ik alle noodzakelijke gaatjes geboord in de plexi. Deze gaatjes (4mm) waren gemakkelijk te boren vermits de FlyEngravity window frames al voorzien waren van voorgeboorde bevestigingsgaatjes. Enkel de gaatjes in de voorste zijramen heb ik nog moeten bijmaken. Vervolgens is het gewoon het gaatje in het window frame volgen doorheen de plexi.

Nadien wordt er door elke gaatje een boutje gestoken en vastgedraaid met het bijhorend moertje (niet te vast, risico voor barsten).

Later kunnen die gemakkelijk verwijderd worden voor de bevestiging van de window liners.

Afwerking

De voorste ramen (windshield) heb ik aan de binnenzijden afgewerkt met een plastieke afboordstrip. Anders kijkt men tegen de afgezaagde plexirand van de plexipanelen en dat is niet zo mooi. De plastieke strip is lichtgrijs gespoten en bevestigd via de boutjes voor de plexipanelen.

Voor de zijramen is er geen verdere afwerking gebeurd. Dit komt later bij het bevestigen van de window liners.

EYEBROW WINDOWS

Buiten de voorste ramen (windshield) en zijramen hebben we de ‘Eyebrow windows’ of de kleine raampjes die zich links en rechts net boven de voorste ramen bevinden.

Ik heb een tweedehandse set op de kop kunnen tikken van waarschijnlijk een B737-300.

Ik heb deze ‘mini’-raampjes ingedeeld bij de ‘Ceiling’ of het plafond van de cockpit. Ze horen ook een beetje bij het interieur.

Alle informatie betreft de renovatie en installatie van deze ‘Eyebrow windows’ is te vinden op volgende pagina :

https://www.flightdeck737.be/hardware/platform/ceiling/eyebrow-windows//

RUITENWISSERS

Ook een onderdeel van de ‘windows’, meer bepaald van het ‘ windshield’, zijn de ruitenwissers (wipers).

Niet dat ik regen verwacht in mijn cockpitroom maar dit is weer een onderdeel om het realisme van de cockpit omhoog te krikken.

De dummie-ruitenwissers zijn vrij gemakkelijk op het ‘windshield’ te monteren. Wat hebben we nodig ?

- 2 ruitenwissers;

- 2 aluminium staafjes;

- 2 metalen L-profielen;

- boutjes met moeren;

- 8 Alu M4 Dzus replica’s.

Ruitenwissers

Ik heb de ruitenwissers gekocht bij Van Cranenbroek in Budel (NL). Deze ruitenwissers zijn van plastiek en kosten bijna niks (+- 3€ per stuk). De lengte van een ruitenwisser bedraagt 38 cm. Deze lengte geeft aan de bovenzijde van het ‘windshield’ een speling van 2 cm. Een lengte van 40 cm zou misschien nog net kunnen …

Aluminium staafjes

De staafjes zijn de hefboompjes (verbindingen) tussen de ruitenwissers en de L-profieltjes. Deze staafjes zijn gezaagd uit aluminium van 2 mm dik. Ze hebben een lengte van 15 cm. De uiteinden zijn met een vijl een beetje afgerond.

L-profieltjes

Deze L-profielen zijn te koop in elke doe-het-zelf zaak. Deze dienen om de alu staafjes met ruitenwissers te bevestigen tegen de window frames.

Staafjes, boutjes, Dzus’s en profielen heb ik in een zwarte kleur geschilderd.

Montage

Eerst heb ik draad getapt (4 mm) in de ruitenwisser en dit op het verbindingspunt met het staafje. Dan heb ik het staafje boven op de ruitenwisser geschroefd met een boutje van 4 mm.

Tussen staafje en boutje heb ik eerst een Dzus replica geplaatst.

Voor de bevestiging van het staafje met ruitenwisser heb ik het L-profiel in het midden en aan de onderzijde van het FlyEngravity- window-frame geschroefd. Het andere uiteinde van het alu staafje wordt vervolgens tegen de voorzijde van het L-profiel geschroefd.

Tussen profiel en staafje heb ik 2 Dzus-replica’s geplaatst en eentje tussen staafje en bout. Deze Dzus’s dienen meer voor de ‘lookalike’ en voor een verschil in niveau weg te werken.