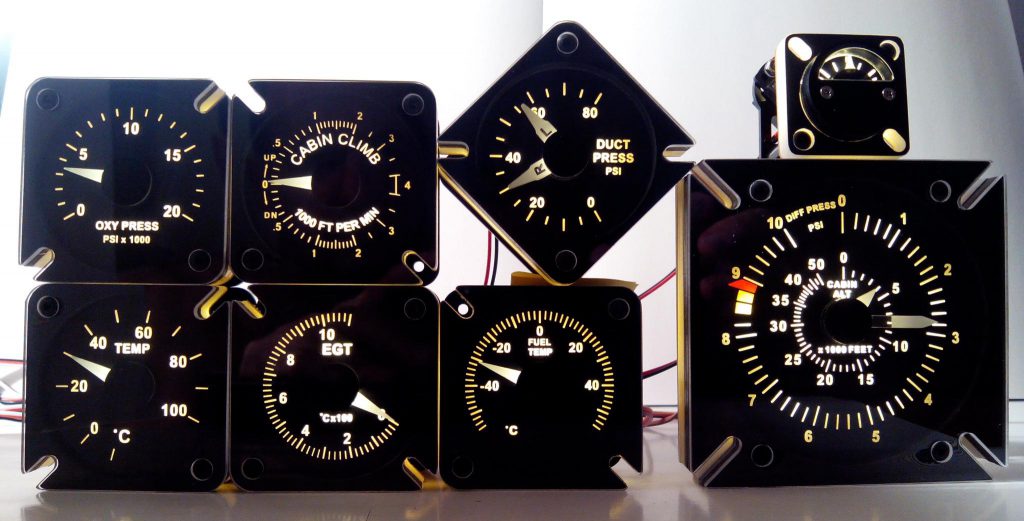

Overhead gauges

OMSCHRIJVING

De FWD- en AFT Overhead zijn samen uitgerust met 8 metertjes of ‘gauges’:

- Fuel Temp

- EGT

- Diff Press en Cabin Alt

- Cabin Climb

- Temp

- Duct Press

- Valve

- Oxy Press

De volledige omschrijving en functies van deze gauges zijn te vinden in de verschillende Boeing 737-manuals die te vinden zijn op het Internet.

Zoals de gauges in de MIP heb ik de OVH-gauges ook gekocht bij Custom Sim Parts.

CUSTOM SIM PARTS

Algemeen

In de wereld van de cockpitbouw kunnen we zeggen dat Flight Illusion zowat de marktleider is betreft het leveren van metertjes, klokjes of gauges. Dit bedrijf heeft dan ook een groot assortiment ter beschikking waar iedereen wel zijn gading in kan vinden.

De gauges van FI zijn gemaakt met degelijk materiaal en mooi afgewerkt. De aandrijving van de FI- gauges gebeurt met steppermotoren.

Een paar minpuntjes zijn dat de FI-gauges vrij duur zijn, niet altijd eenvoudig om te configureren en geen realistische backlighting hebben.

Er zit een ledje aan de voorzijde van de frontplaat die de voorzijde verlicht, sommige FI-gauges zijn nog uitgerust met een TL-achtige witte led (Ice white of keukenlicht). Hierbij is er dus geen sprake van ‘backlighting’…

Toevallig, via het Prosim737-forum, ben ik terecht gekomen bij Custom Sim Parts. Dit bedrijfje maakt ook gauges maar voorlopig in beperkte mate. Op het tijdstip van dit schrijven zijn dat enkel de B737 MIP-gauges zoals Flaps, Brake Pressure, Yaw Damper en alle B737-Overhead gauges.

Wat maken de gauges van Custom Sim Parts zo interessant :

- Goedkoop;

- Alle gauges kunnen ‘custom-made’ gemaakt worden volgens de wensen van de klant;

- De backlighting is zeer realistisch en mooi;

- Heel eenvoudige installatie en gemakkelijke configuratie;

- Kunnen gebruikt worden met de Pokeys Microcontrollers + Led extension board en Prosim737 voor een realistische backlight-aansturing.

Afmetingen

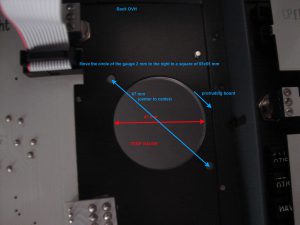

Bij de eerste contacten met Custom Sim Parts wordt gevraagd de afmetingen (diameter) door te geven van de gauge-openingen in de MIP of Overhead. Dit samen met de afmetingen tussen de verschillende boutgaatjes waarmee de gauge moet bevestigd worden.

Om de afmetingen nog extra te verduidelijken kan men ook wat close-up foto’s van de voor- en achterzijde van de Overhead erbij voegen.

Op kritische plaatsen waar weinig of niet voldoende ruimte is, wegens de aanwezigheid van een schakelaar of een printplaat, dan kan er altijd gezocht worden naar een oplossing door bv. de gauge kleiner of in een andere vorm aan te leveren (bv. ruitvorm).

Nadien ontvangt men van Custom Sim Parts een tekening met de voorgestelde gewenste afmetingen voor goedkeuring.

Hierbij een voorbeeld van CSP met voorgestelde afmetingen:

FlyEngravity OVH-gauges dimensions

Deze tekeningen print/knip ik uit op ware grootte om af te passen in de Overhead. De cirkel van de gauge moet passen met de opening in de OVH samen met de openingen voor de bevestigingsboutjes.

Indien de de gauge-openingen in de MIP en OVH al zijn uitgerust met een glasplaatje kan men ook de CSP-gauges bestellen zonder glas aan de voorzijde.

Aansturing

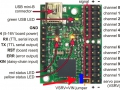

De aansturing van de gauges gebeurt via standaard digitale servo’s en dit samen met een Pololu Servo Controller. Hiervan bestaan 2 versies :

De 6-Channel versie wordt meestal gebruikt voor de MIP en de 12-Channel voor de Overhead.

Met de 12-Channel controller kan men desnoods MIP+OVH ook samen aansluiten, alleen is de afstand OVH>MIP naar de Flaps- en Brake Pressure gauge een hinderpaal …

Daarom is het eenvoudiger voor de MIP en OVH apart een controller te gebruiken.

De overgebleven vrije poorten op de controller kunnen nog altijd gebruikt worden voor digitale Inputs/Outputs. Helaas is Prosim737 niet compatibel met deze Input/Output kanalen. Enkel de Servo-kanalen worden herkend door Prosim737. Dat is een beetje jammer …

Deze Pololu Servo Controllers zijn volledig geassembleerd. Ze zijn erg klein (30 mm x 20 mm) en zijn dus gemakkelijk weg te werken achter de Mip of in de OVH.

Backlighting

De backlighting gebeurt via een led (20 mA) die achter de frontplaat is geïnstalleerd. De kleur van de backlight kan men kiezen en is dus optioneel.

De standaardversie is ‘warm wit’. Maar men kan ook kiezen voor een Amber-kleur.

Mijn FlyEngravity MIP en OVH-paneeltjes zijn al uitgerust met een warme-witte backlighting. Daarom heb ik ook gekozen voor ‘warm-wit’ als backlighting voor de MIP- en OVH gauges.

De backlighting kan aangedreven worden via de Pololu-controllerpoort met een bijgeleverde splitterkabel.

Ook is het mogelijk de backlighting aan te sturen op meer realistische manieren (zie apart hoofdstuk hieronder).

SERVO MOTOREN VS STEPPER MOTOREN

Gauges kunnen aangedreven met servo’s of steppermotoren. Beide manieren hebben hun voor- en nadelen.

http://www.modmypi.com/blog/whats-the-difference-between-dc-servo-stepper-motors

http://www.arrickrobotics.com/motors.html

De gauges van ‘Custom Sim Parts’ zijn uitgerust met digitale RC servo’s. Waarom?

- Servo’s zijn veel gemakkelijker te implementeren dan stappenmotoren en veel goedkoper;

- Ze kunnen worden aangesloten op elke standaard servo-controller wat de gauges universeel of algemeen toepasbaar maken;

- Servo-controllers zijn erg goedkoop en er is veel keuze in;

- In de handel is het niet gemakkelijk een combinatie te vinden van een steppermotor met controller tegen een vergelijkbare prijs als bij servo met controller.

ONDERDELEN

Welke onderdelen hebben we allemaal nodig om de CSP-gauges te installeren :

- CSP- gauges;

- Pololu servo controller (6 Ch/12 Ch of beiden);

- USB kabel (USB 2.0 Cable – A-Male to Mini-B – 1.8 meters) ;

- Connectors + kabels voor de verbinding te maken tussen servo controller en de gauge(s);

- Een oude Pc power supply voor de 5V;

- Bouten en moeren M4 met een lengte van 25 mm;

- Drivers voor de Pololu servo Controller.

Alle kabels en connectors worden gratis erbij geleverd (behalve de USB-kabel) ?. De kabels en connectors zijn ook ‘custom made’ d.w.z. dat ik zelf de afmetingen en lengtes bepaald heb van de verschillende kabels. Ze zijn mij netjes opgestuurd zoals ik had gevraagd en dit zonder meerprijs.

INBOUWEN VAN DE GAUGES

Het inbouwen van de gauges in de behuizing van de Overhead verloopt vrij gemakkelijk. Natuurlijk moeten de openingen voor de bevestigingsbouten overeenkomen met de openingen in de gauges.

Daarom is het zeer belangrijk voordien de juiste afmetingen door te geven aan CSP.

Ook de afmetingen voor de gauge zelf zijn belangrijk d.w.z. de diameter van de opening in de ‘Overhead’ en de max afmetingen van de omtrek van een gauge. Zoals bij een ICS-systeem zit de ‘Overhead’ vol met printplaten (pcb’s) en is het soms krap aan ruimte om een gauge te kunnen plaatsen.

Volgens de wensen van de klant kan CSP de gauges aanpassen in groottes en volgens de gewenste afmetingen. Zelfs de cirkel van sommige gauges heb ik laten opschuiven naar links of rechts in de behuizing van de gauge.

Ik heb bv. ook gevraagd om wat veranderingen uit te voren betreft de kleur:

- EGT- gauge > tekst “°C x 100” in blauwe kleur;

- Cabin Climb- gauge > tekst “1000FT PER MIN” in blauwe kleur.

Alles is dus mogelijk …

De bevestiging van een gauge is uitgevoerd met 2 bouten van elk 4 mm dik (4M) en een lengte van 25 mm. De boutjes heb ik eerst geschilderd in Boeinggrijs.

Opm. Tijdens de bevestiging van de Temp-gauge heb ik kunnen ondervinden dat de openingen voor de bevestiging aan de verkeerde kant waren aangebracht. Ik heb deze fout dan ook gemeld aan CSP. Twee weken later zat er een nieuwe gauge in de brievenbuis met de openingen op de juiste plaats. Top service! En vergissen is menselijk …

INSTALLATIE EN AANSLUITEN VAN DE POLOLU SERVO CONTROLLER

1. Installeer de Pololu-drivers met het ‘Maestro Control Center’:

Maestro Servo Controller Windows Drivers and Software (release 130422) (5MB zip)

Dit ZIP-archief bevat de installatiebestanden voor de Pololu Controller met het ‘Maestro Control Center’, de ‘Maestro Command-Line utility en de Pololu Maestro Servo Controller-drivers voor Windows.

2. Aansluiten van de Pololu Servo Controller met de USB kabel:

De Pololu Servo Controller moet aangesloten worden aan de pc waarop Prosim737 is geïnstalleerd. Dit gebeurt met een USB Mini verbindingskabel

(USB A, mannelijk <=>USB B, mannelijk 5-pin – 3m).

Deze usb-kabel heb ik gekocht bij Allekabels.nl. De kabel van 3m heb ik door het holle metalen frame van de cockpit getrokken tot in de kast van de Fwd Overhead. De Pololu Servo Controller heb ik boven in de kast van de Fwd Overhead bevestigd. Deze Pololu Servo Controller is zeer klein en kan gemakkelijk ergens in de Overheadbehuizing geplaatst worden.

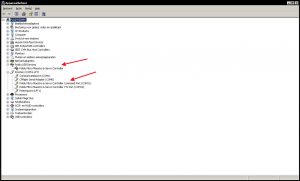

3. Verifieer of in ‘Apparaatbeheer’ de Pololu USB Controller geïnstalleerd is:

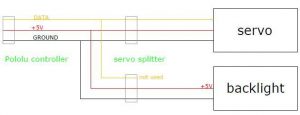

4. Verbindt de servo’s van de gauges (en de backlighting) met de controller:

Optie 1 > De gauge is voorzien van 2 bundeltjes kabeltjes : kabels die komen van de servo en een bundeltje voor de backlighting.

Beiden worden met een splitterkabel verbonden met de controller.

Bij deze optie is de backlighting enkel rechtstreeks aangestuurd door de micro controller en niet door Prosim737. Wanneer de Pololu micro controller onder spanning staat zal ook de backlighting van de gauges beginnen te branden of op te lichten. Bij een Cold&Dark cockpit is dit dus niet realistisch. Het gebruik van een tussenschakelaar in de cockpit kan hierbij een oplossing bieden.

Optie 2 > Bij de gauges van mijn OVH blijven de aparte connecties voor de servo’s en backlighting gescheiden. Op de achterzijde is de gauge uitgerust met 2 pinnetjes voor de backlighting (niet standaard). Op deze 2 pinnetjes wordt er een verlengdraad (extension) aangesloten die aan de andere zijde wordt verbonden met de Pokeys Led Extension Board. Verdere uitleg over deze verbinding in een volgend hoofdstuk.

Voor de servo’s vertrekken er 3 (korte) draden met connector aan het uiteinde. Hieraan worden ook verlengdraden (extensions) op aangesloten om de afstand te overbruggen tussen gauge(servo) en de Pololu Controller (dit is op aanvraag van de klant).

Bij deze optie wordt de backlighting volledig gestuurd door Prosim737 en dit door gebruik te maken van de Pokeys Led Extension Board en een Prosim-gate ‘AC Power’. Bij het opzetten van AC Power (Gnd Pwr, APU, Generators) wordt de backlighting van de gauges ook actief.

De platte stekkers of connectors voor de servo’s bevatten 3 aansluitopeningen : 1 witte voor het signaal en de twee anderen voor de + (rood) en de – (zwart).

De blauwe ‘jumper’ wordt geplaatst zoals op de afbeeldingen.

5. De controller aansluiten met de 5V-voeding

De 5V-voeding kan men halen van een oude pc-voeding. Meestal is een homecockpit al uitgerust met zo’n ‘Power Supply’-bakje en kunnen we daarvan wel ergens aftappen. Het plat stekkertje voor de controller heeft maar 2 aansluitingen, + en – . De derde wordt niet gebruikt.

Zie afbeeldingen voor de juiste aansluiting.

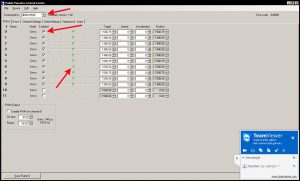

CONFIGURATIE VAN DE POLOLU SERVO CONTROLLER IN HET MAESTRO CONTROL CENTER

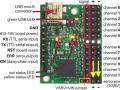

6. Open ‘Maestro Control Center’ en controleer of de controller is verbonden (‘Connected to’ gevolgd door de juiste kaartnummer).

7. Schakel de toegewezen kanalen in (0-1-2-3-4-5-6-7-8-9) door een vinkje te plaatsen in het vakje (enabled);

Opm. De ‘Diff Press’ en ‘Duct Press’-gauges hebben een dubbele servo.

8. Controleer als test de servo door het bewegen van de sliders met het groene bolletje. De wijzer van de gauge moet samen met de slider bewegen;

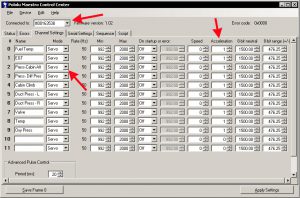

9. Ga naar de ‘Channel Settings’ -tab;

10. Vul bij elk kanaal de namen in van de gauges en zet alle kanalen bij ‘acceleration’ op 1 (dit dient om de naalden of wijzers van de gauges vlotter te laten bewegen);

11. Klik op ‘Apply Settings’ en sluit het programma.

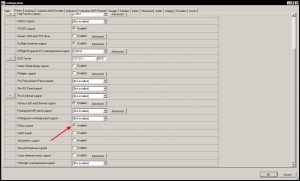

CONFIGURATIE VAN PROSIM737

12. Start Prosim737;

13. Open Configuration/Drivers;

14. Enable Pololu support door een vinkje te plaatsen;

15. Ga naar de Gauges-tab;

16. Scroll naar onder naar de juiste gauge;

17. Kies de juiste Maestro Controller in de dropdown-lijst;

18. Kies het Pololu-kanaal waaraan de gauge is verbonden;

19. Configureer met de sliders de juiste instelling van de gauge en druk OK;

20. Open Flight Simulator en doe een test. Maak desnoods correcties indien nodig.

VIDEO

DE BACKLIGHTING REALISTISCH ACTIVEREN

Zoals de verbindingen van de backlighting hierboven zijn omschreven in Optie 1 en men steekt de stekker in het stopcontact dan brandt de backlighting van alle gauges. Niet bepaald een echte ‘Cold&Dark’-situatie en dus ook niet realistisch …

De backlighting zou volgens de Boeing-manuals enkel actief mogen worden wanneer de cockpit onder AC-power staat. Dit is na het opzetten van de Ground Power, APU of bij actieve Generators.

Hoe kunnen we dit simuleren met de CSP-gauges en welk zijn de eventuele mogelijkheden?

- Sluit de backlighting van de gauges rechtstreeks aan op 5V en plaats er een schakelaar tussen. Wanneer de cockpit is overschakeld naar AC-power zet je de schakelaar op;

- Gekoppeld aan de schakelaar van de ‘Ground Power’ (via een laagspanning – hoge weerstand – ‘reed relais’ met een apart circuit van 5V of 12V). Wanneer de schakelaar van de ‘Ground Power’ wordt gebruikt zal de relais naar On/Off gaan en ook de backlighting schakelen.

Maar dan is men wel afhankelijk van enkel de ‘Ground Power’ … - Een relaiskaart met digitale Outputs en die compatibel is met Prosim737. In de Prosim737-configuratie wordt dan een ‘Gate’ gebruikt;

http://www.phidgets.com/products.php?category=9&product_id=1014_2 - Het gebruik van Output kanalen in de Pololu Maestro Controller en deze koppelen aan een ‘Gate’ in Prosim737 (zoals vermeld in voorgaande).

Helaas is dit niet mogelijk vermits Prosim737 niet compatibel is met de In/Output kanalen van de Pololu Controller. Op het tijdstip van dit schrijven is Prosim737 enkel te gebruiken met de Pololu servo-kanalen; - Het gebruik van een Pokeys Microcontroller en een bijhorende ‘Led extension board’. In de Prosim737-configuratie wordt dan een ‘Gate’ gebruikt.

Vermits ik één van de (eerste) gebruikers ben van de Pokeys interfacekaart en de ‘Led extension board’ heb ik deze optie ook onderzocht samen met Custom Sim Parts en FlightSimParts.eu (Wendy).

Na de nodige testen vond ik dit de juiste, gemakkelijkste en goedkoopste oplossing om de backlighting realistisch aan te sturen.

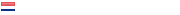

Aansturing van de backlighting via de Pokeys Microcontroller, ‘Led extension board’ en Prosim737

Hierbij volgt een stappenplan om de Pokeys, de ‘led extension board’ en Prosim737 te configureren zodat de backlighting van de gauges begint op te lichten bij het inschakelen van AC power:

- De OVH-gauges zijn aan de achterzijde allemaal uitgerust met 2 pinnetjes voor het aansluiten van de backlighting (niet standaard).

Vermits de backlighting apart wordt aangesloten via de Pokeys en de Pokeys Led Extension Board heeft men dus elke gauge voorzien van 2 pinnetjes. Het vergemakkelijkt de aansluiting omdat men dan de lengte van de draden zelf kan bepalen en de (-) en de (+) van elkaar kan scheiden. Bijhorende kabels met connectors (extensions) zijn gratis bijgeleverd. De klant bepaalt de lengte van de kabels.

Om de afstand te overbruggen tussen de kast van de Overhead en de Pokeys Led Extension Board (achterzijde MIP) heb ik een netwerkkabel getrokken door de buizen van het holle metalen cockpitframe.

De netwerkkabel is vanbinnen samengesteld uit 8 draadjes. Net genoeg voor 8 gauges … En de verschillende kleuren van de draden kunnen als gids dienen welke draad verbonden is met wat. - Verbindt het ene uiteinde van de extensiondraad+connectors aan de 2 pinnetjes van de gauge. (Later bij het testen kan het zijn dat de backlighting niet werkt. Dan moeten de draadjes gewoon verwisseld worden van plaats). Linkse pin is (+) en rechtse pin is (-).

- Verbindt de (+) draden van de backlighting parallel met elkaar en verbindt de laatste door naar de gemeenschappelijke (+) van de ‘Led extension board’. De gezamelijke verbindingen van de (+) draden zijn gemaakt met verbindingsklemmen.

- Verbindt vervolgens de (-) draden van de backlighting één voor één aan een aparte draad van de netwerkkabel. Deze verbinding heb ik tot stand gebracht door eerst de draad van de netwerkkabel te strippen en vervolgens om te plooien. Het omgeplooid gedeelte kan je dan in de connector drukken van de gauge. Om alles af te schermen en te beveiligen heb ik er een krimpkous overheen getrokken.

- Aan de andere zijde van de netwerkkabel wordt elke draad weer eens apart verbonden met een vrije poort van de ‘Led extension board’.

(De ‘Led extension board’ is verdeeld in 2 delen : de ene helft is waar de leds worden aangesloten en de andere helft waar de aansluitingen gebeuren naar de Pokeyskaart).

(Op de ‘led extension board’ kan men per poort verschillende leds aansluiten en dit tot max 300 mA. De CSP-gauge is uitgerust met een led van 20 mA. De backlighting van verschillende gauges kunnen dus eventueel gezamenlijk worden aangesloten op één poort). - Maak vervolgens een verbinding tussen een willekeurige poort op de Pokeys Microcontroller naar een poort op de Pokeyszijde van de ‘Led extension board’. Deze poort ligt tegenover de poort waar we de Ledverbinding hebben gemaakt (bv. Poort 8 aan de ledzijde = Poort 8 aan de Pokeyszijde).

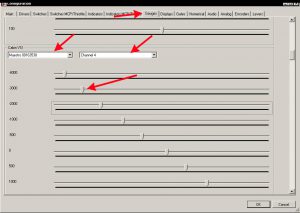

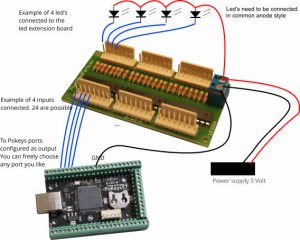

- Activeer in de Pokeys configuratiesoftware (Poscope) de desbetreffende poorten als digitale Output (in ons voorbeeld Poorten 4 t/m 11);

- Dan openen we Prosim737 – Configuartion – Gates en kiezen we in de lijst ‘AC Power’ met erachter de juiste Pokeyskaartnr en de juiste poort.

Om een extra lijn bij te maken met ‘AC Power’ drukken we het +teken.

Opm. Niet vergeten dat hierbij ook eventueel de gauges van de MIP bijstaan (flaps, brake pressure, yaw damper).

Wanneer we nu de cockpit onder AC Power zetten (bv. Ground Power, APU of generators) gaat de backlightverlichting van de gauges oplichten.

CONCLUSIES

De prijzen van de Custom Sim Parts-gauges zijn erg goedkoop.

Custom Sim Parts is zeer flexibel en klantvriendelijk. De gauges worden gemaakt volgens de wensen van de klant.

Voor moeilijke setups en aansluitmogelijkheden worden oplossingen gezocht.

De lead time van 3 à 4 weken voor het bouwen van de gauges en het versturen van de bestelling wordt gerespecteerd.

De gauges van CSP zijn mooi en degelijk afgewerkt. De openingen voor de bevestigingsboutjes zitten op de juiste plaats zoals voorzien is op de tekeningen en waarbij het bevestigen zeer vlot verloopt. Idem voor de verschillende aansluitingen.

Eventuele fouten worden onmiddellijk beantwoord door het versturen van een nieuw exemplaar.

Wanneer men bij de configuratie het stappenplan met foto’s/video’s volgt is dit een gemakkelijk en eenvoudig werkje. A piece of cake …

De backlighting van de gauges is realistisch en prachtig om naar te kijken.

De naalden of wijzers van de gauges bewegen vlot en soepel zonder te schokken.

De contacten met Custom Sim Parts (Tom Kaminski) zijn vlot en snel. Tom is zeer hulpvaardig voor geven van adviezen of het zoeken naar oplossingen.

Emails worden binnen de 24Hr beantwoord.

De duurzaamheid van de gauges is nog niet te bepalen wegens de recente ingebruikname en de komst van het nog nieuwe Custom Sim Parts als bedrijfje.

Zeker een aanrader!