Rudder pedals / stands

RUDDER PEDALS

The rudder (rudder) of an aircraft that is not operated by the flight controls (yoke?), but the pedals (rudderpedals). Also, the brakes are operated.

The rudder pedals which are in the flightdeck of a setup (for now) going to use this from the Saitek Pro Flight Rudder Pedals). They will be in this setup are integrated into the left-hand rudder position.

SPECIFICATIONS

- Self-centering pedals with adjustable damping

- Adjustable foot rests to fit all sizes, with non-slip materials

- Fully adjustable rudder control to suit the gamer's preferences.

- Tension adjustment to vary resistance to suit flying style

- An Advanced SST Programming

- Allow the brakes.

RUDDER STANDS

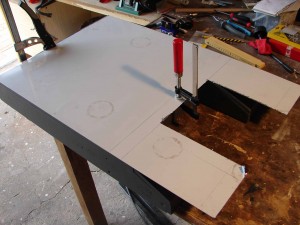

The ruddercompartiment is made of 3 parts :

- Ruddervloer

- Stand-up rudderstand

- ‘Rudder Pedal Adjustement’

The ruddervloer on the part of the MDF board of 18 mm thickness. In this context, it is at the top, covered by a sheet of plywood is a panel of up to 12 mm in thickness. Everything has been fixed with chipboard screws.

The dimensions are in accordance with the supplied MIP level. The height is a little higher (to 90 mm) than that in the real (70). This is because I will have to take into account the height of the lower yokegedeelte. In this block, the yoke would have to be equal to the ruddervloer. The USB port on the yoke will be on the way out of sight.

The whole thing is still in it, and pull out.

To be realistic, to make them come true will make this ruddervloer covered with an aluminum plate of 1 mm or less. This will be done after the painting of the MIP-mode.

The one that create this stand-up rudderstand it was not very easy. All of the measurements I had, and only the length (164 mm). In addition, it was a bit of a gamble with the height, I had to take into account the height of the lower panels as well as the size of the Rudder Adjustement’block, which is still up on the edge of the rudderstand to do. This last one I didn't size.

Not to mention, it was very important to get the right angle of the oblique front side. The angle is too small, then the horizontal leg is too far back, so with the Rudder Pedal Adjustement’block. If it Is too large, everything will be back up and running to the front to stand up. The angled front, if it's not too long or too short.

In the context of the stand-up rudderstand is also made from MDF board of 18 mm thickness. The upper bevel and the front side is sealed with MDF board of 6 mmdikte. This was, however, until and meetwerk to look at the transition from horizontal to oblique and vertical, square to bring them into line. Using a jigsaw, cut on a 45° turn, this is easy to solve the problem. But it does take a bit of practice...

Furthermore, it is MDF, very easy to use, and easy to work. With some sanding it's nice and overcast.

At the bottom, on the Apt side, and has a section cut out for the rudder (Saitek Pro Flight Rudder). Here, it is taken into account and that the rudder is still in the front and can be moved around.

In this section, the ‘Rudder Pedals’, as well as to set up the pilot behind the controls is . One of them has longer or shorter legs than the other.

Because of this, my own personal jet, and I have no other pilots are expected to be in the ‘captain's seat’, the ‘rudder pedals’ is also set to my personal preference. This is the Rudder Pedal Adjustement " pads are so fake, and should be used as dummies. Again, in order to add a little more in-depth, and more realistic, to make them come true...

As I said in the previous paragraph, I mentioned I had these EPS-block of any size. But a photo search on Airliners.net and the magnifying glass icon is installed. And then all of the details, but the study and the conditions to assess and drawing on paper and then on wood. Ultimately, the result is to be seen. The paint job is all in the right colour with the right text plates.

The framework is also patched together with the MDF board of 18 mm thickness. The front panel is made of MDF board of 6 mm thickness. It's a square image (cube) of up to 12 mm in thickness, and it is a small picture of draaihandvatje " (6 mm) thick.

The draaihandvatje is a shortened version of one of the seized spool of thread out of the naaikoffer of his wife. The lever that the draaihandvatje is attached to the EPS-block) is a gemotificeerd point of view, a Cherry-ijslolly.

It has to be somewhat cheap to stay...

The vertical sides are made up of MDF board of 12 mm thickness.

As a tool for the construction of this ruddercompartiment is a thorough study of the various flightdeckfoto on Airliners.net. Dozens of pictures have passed, and it was, for me, is a very important tool for the crafting of this section of the dashboard.

The the Rudder Pedal Adjustment units have been painted and finished off with buttons and placards, and also to include the appropriate text and graphics.

To the right of text and figures that are on the Rudder Pedal Adjustment sections to come were still there. He Belmans has given me the necessary photos were taken in a real cockpit, and it passed.

The graphics I make ‘In-Sight’ a company, at home, at the corner of which is occupied by advertisements, banners and graphics of all kinds, and it is of tiny to large stickers on the vehicles stick to it.

The engraving work (placards) do I have to make a Trophy-Shop Lambert Noten in Neerpelt.

The installation of the small numbers and letters, it was prutswerk, and a steady hand was needed ...

With the release of the handles with made out of the empty garenklosjes has now been replaced by handles with which turned out of plasticErtalon). The size of the cylinders 35 mm long and the sides are 25 mm in width, with a taper of 20 mm.

This one is a bit more realistic.

My special thanks to the Dec System for the manufacturing of these handles with.

As the real versions...

Aluminiumbekleding of the ruddervloer

It is the position of the ruddervloer (2-pack), it is more cut-and-paste work. First, I have 2 of the aluminum sheets obtained from Staalhandel Vaesen, in Overpelt. This company is in my back yard, and easy to spot.

These aluminum panels are each of a size of 470 mm x 800 mm and One thick and cut to size. 470 mm, the width of the ruddervloer and 800 mm total length including the bent-up portions, plus a kleinoverschotje. These aluminum plates are one side coated with a the white plastic sheet in order to prevent the surface while the work is being damaged.

For the record, I have the ruddervloer been laid, and the width equal with the edge of the wooden base and secure with the soldiers wish to find, or houtklemmen. I then used the flat parts of the edges to be screwed with Stainless steel chipboard screws flat head (3.0 x 16). In order to have the flat heads, as well as possible, to let it sink in that the aluminum plate have a plate where the screws will need to come to be slightly drilled out. Not too much, since 1 mm is not thick. Be careful with the screws already in the wood base !

For the record, I have the ruddervloer been laid, and the width equal with the edge of the wooden base and secure with the soldiers wish to find, or houtklemmen. I then used the flat parts of the edges to be screwed with Stainless steel chipboard screws flat head (3.0 x 16). In order to have the flat heads, as well as possible, to let it sink in that the aluminum plate have a plate where the screws will need to come to be slightly drilled out. Not too much, since 1 mm is not thick. Be careful with the screws already in the wood base !

Then it was the turn of the plooiwerk. The plooilijnen I got to the edge of the MDF panel (18mm) fixed, and then another sheet of plywood panel evenly to the folding section, to be printed, together with the wooden base. And then, all of the edges and screwed down with stainless steel chipboard screws.

Then it was the turn of the plooiwerk. The plooilijnen I got to the edge of the MDF panel (18mm) fixed, and then another sheet of plywood panel evenly to the folding section, to be printed, together with the wooden base. And then, all of the edges and screwed down with stainless steel chipboard screws.

Braamrestjes, and redundant edges are eliminated, with the metaalvijl.

Braamrestjes, and redundant edges are eliminated, with the metaalvijl.

The sides of the ruddervloeren immersed in the MIP-support, and, therefore, will not be visible, it will not be lined with aluminum. The only thing visible on the front of it. The excess of the 800 mm length is used for the coating of the side walls. Also, here is the easy to measure, and measuring. Prefer to to 01 mm and is more than enough. Excess can be removed easily with the metaalvijl.

The corners and edges of the metaalvijl a beautiful place.

The sawing was done with an electric decopeerzaag with a fine blade designed for both wood and aluminum.

Translated by Yandex.Translate and Global Translator