DV Window Armrest/Chart holder

OMSCHRIJVING

De ‘Window Liners’ zijn de raamkozijnen (raamomlijstingen) die men kan vinden tegen de verschillende raamframes.

Je kan ze kant-en-klaar kopen bij sommige firma’s die cockpit stuff verkopen. Algemeen zijn ze erg prijzig en ze moeten ook net passen met het window frame dat men gebruikt.

Het is dan ook de bedoeling mijn ‘Window Liners’ zelf te maken.

De ‘Window Liners’ zijn onderverdeeld in :

- Middle strut windshield window liner;

- Side window armrest/Chart holder (Capt en F/O);

- AFT Lower window liners (Capt en F/O);

- AFT Upper/Middle window liners (Capt en F/O);

- FWD Upper/Front window liners (Capt en F/O);

- Imitation glass (plexi or pvc).

De ‘DV window armrest/chart holder’ is te vinden aan de onderzijde van de voorste zijramen. Op deze ‘DV window armrest/chart holder’ is een ‘Chart Holder Clip’ met bijhorende plaat bevestigd, dit om vliegkaartjes onderin te plaatsen.

Aan de voorzijde is ook de (dummie) hendel bevestigd om het voorste zijraam te openen.

Uitleg van de verschillende opbouwonderdelen van de ‘Window Armrest/Chart holder is te vinden op volgende pagina : https://www.flightdeck737.be/hardware/platform/zijpanelen/inopbouwonderdelen-new/

PROCEDE MET AFWERKING

De ‘Arm Rest’ is niet gemaakt met het piepschuim/polyesterprocedé maar van MDF-panelen. Dit vooral omdat dit onderdeel regelmatig wordt aangeraakt tijdens een vlucht (vliegkaartjes ophangen) en daarom moet dit toch de nodige stevigheid hebben.

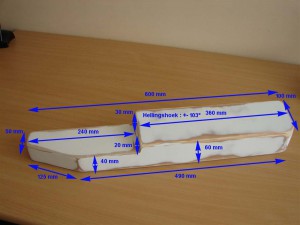

De afmetingen die ik heb gebruikt is wat betreft lengte even lang als de onderzijde van het aluminium frame van het zijraam. Verder heb ik mij gebaseerd op foto’s en een paar afmetingen die genomen zijn uit een echte B737.

Persoonlijk vind ik mijn exemplaar geslaagd, achteraf bekeken mag de dikke zijde één centimeter dunner zijn. Het schuine blokje er bovenop is iets te dik uitgevallen …

Over de ganse lengte heb ik 2 MDF-paneeltjes van 18 mm dikte en die op maat gezaagd en nadien op elkaar gelijmd. Een nadeel van MDF is het gewicht.

Het schuins opgaande gedeelte is uit een stuk hout op maat gezaagd (iets te dik uitgevallen). Dit gedeelte is op zijn beurt bovenop op de MDF-paneeltjes gelijmd. Nadien is alles nog eens extra bevestigd met een 3-tal houtschroeven.

Vervolgens worden alle hoeken waar nodig rond afgeschuurd.

De oppervlaktes rondom de ‘armrest’ zijn dan bewerkt met polyesterplamuur om alle gaatjes en spleten weg te werken. Nadien wordt alles volledig glad geschuurd met heel fijn schuurpapier (korrel 240-320). Misschien is plamuur aanbrengen meerdere malen noodzakelijk totdat alle gaatjes of openingen verdwenen zijn. Je kan dat best doen na eerst een primer aan te brengen, dan zie je veel beter de overblijvende spleten en gaatjes.

De ‘armrest’ heb ik vervolgens in het zijraam gemonteerd op de onderste zijde van het aluminium frame. En dit onder een hoek die + – overeenkomt met de boord van het frame (115 graden).

De montage is uitgevoerd met een paar boutjes door de onderzijde van het windowframe en de blok van de ‘armrest’.

Hiervoor heb ik aan de onderzijde van de ‘armrest’ moerklauwen gebruikt waarbij je eerst een gaatje boort dat iets groter is dan de dikte van de bout en vervolgens wordt de moerklauw in het boorgaatje gedrukt en in het hout geklopt met een hamer. De bout komt dan door het metalen frame en wordt in de moerklauw gedraaid.

De blok van de ‘armrest’ is een heel gewicht maar wordt later nog ondersteund door de onderliggende balk.

Als afwerking krijgt de ‘Armrest’ een Boeing-grijze kleur en aan de voorzijde wordt deze voorzien van het raamhandvat met montageplaat. Op het dik gedeelte komt er een metalen plaatje met klipbord. En als afwerking dan nog de ‘decals’ op de zijkant.