Rear ceiling

De ‘ceiling’ of dak van de cockpit is onderverdeeld in 3 delen :

- Voorzijde (front ceiling) met inklapbare handgrepen;

- Eyebrow windows met map lights;

- Achterzijde (rear ceiling) met opbouwelementen en decals.

OMSCHRIJVING

De ‘rear ceiling’ is het achterste gedeelte van de cockpithemel die aansluit met de ‘Eyebrow windows’.

Dit achterste gedeelte omvat het dakgedeelte in (bijna) witte kleur dat uitgerust is met verschillende nissen, luikjes en panels :

F/O zijde :

- Speaker;

- Verlichting ‘Circuit breakers’;

- Luikje ‘Emergency escape rope’;

- ‘Air vent’ rooster;

- Luik ‘Spare Bulbs’.

Capt zijde :

- Speaker;

- Luikje ‘Emergency escape rope’;

- ‘Air vent’ grill;

- ‘Eyeball vent.

De vorm en afmetingen van de ‘rear ceiling’ is volgens persoonlijke opmetingen in mijn cockpit en komen niet overeen met de echte versie. Dus afmetingen van mijn versie zijn niet vermeld.

De doelstelling was de opening achter de ‘Eyebrow windows’ dichtmaken en dat zoveel mogelijk overeenkomstig met het echte exemplaar.

Ook het uitzicht en uitrusting van de ‘rear ceiling’ verschilt van type vliegtuig. Ik heb gemerkt dat er verschillende uitvoeringen zijn uiteenlopend, van een ouder B737-800 model, een nieuwere en de NG’s. De opbouw van de ‘rear ceiling’ is telkens verschillend. De cockpitbouwer bepaalt hier welke voorkeur hij wilt volgen…

Betreft de afmetingen van de verschillende opbouwelementen, de paneeltjes die tegen de ‘rear ceiling’ moeten komen, is dit weer zonder verkregen afmetingen. Dit is gebeurd op ‘raming’ (schatting) en dit na het bestuderen van verschillende foto’s van de echte uitvoeringen. Ook weer rekeninghoudend volgens de persoonlijke cockpitsetup.

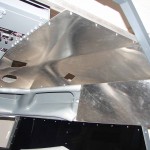

CONSTRUCTIE

De constructie van de ‘rear ceiling’ was niet eenvoudig. Het is een verzameling van vormen en omlijningen die juist moeten zijn. Dit met veel hoeken, bogen en plooien en dat alles in één stuk.

Voor de ‘rear ceiling’ heb ik aluminium gebruikt van 1 mm dik. Sommige cockpitbouwers gebruiken hout of forex. Alleen met hout of forex is het niet mogelijk hoeken te plooien.

Waarom hoeken ?

Je kan ook een gebogen hemel maken van hout, forex of aluminium maar er moeten ook paneeltjes tegenaan gemaakt worden en een vlak geheel (het paneeltje dus) kan men niet mooie vlak tegen een gebogen achtergrond maken. Daarom zijn die hoeken (+ plooien) noodzakelijk om vlakke delen te creëren in de ‘rear ceiling’.

Papier en karton

Eerst heb ik de vorm moeten bepalen met behulp van papier en karton.

Ik heb een aantal A3-vellen aan elkaar geplakt en die over de ‘Eyebrow windows’ gelegd om de omlijningen of contouren van de ‘Eyebrow windows’ uit te tekenen.

Vervolgens heb ik dit overgetekend op ruwe karton. De karton heb ik dan in één stuk bevestigd tegen de ‘Eyebrow windows’ en zijkant overhead.

Eerst gebeurt de uitpassing van de ‘Eyebrow windows’ en de zijkant Overhead, dit om een mooi en recht begin te krijgen.

Achterzijde is niet zo belangrijk. Eerst met wat overschot, achteraf kan men dit nog juist op maat afzagen.

Het moeilijk gedeelte is vooral de buitenzijde van de ‘rear ceiling’ (gedeelte boven de ramen). Hier moet de ‘rear ceiling’een bocht maken naar onder waarbij verschillende plooien aan te pas komen. Dit voor de bevestiging op de bovenzijde van de window frames, de bevestiging zijkant ‘Eyebrow windows’ en de bevestiging tegen de binnenzijde van de benen van het cockpitframe.

Daarom is eerst het gebruik van papier en karton erg nuttig. Je kan naar hartenlust proberen en uittesten totdat je de juiste vorm hebt gevonden.

Daarna wordt de karton bevestigd op alle bevestigingspunten zoals het met de aluminium (definitieve versie) zou moeten gebeuren. Nadien kan je zien of er nog ergens tekortkomingen of fouten in zitten.

Vervolgens kan men op de karton de verschillende openingen uittekenen zoals de opening van de ‘speaker’, de nis van verlichting ‘circuit breakers’ en eventueel van het luikje van de ‘Emergency Escape Rope’.

Deze openingen zijn naar eigen keuze. Ik heb mij beperkt tot de speaker, nis verlichting ‘circuit breakers’ en een kleine opening aan het paneel van de ‘Emergency Escape Rope’. Dit luik is ‘dummy’ en moet dus niet functioneren. De opening is enkel om het zwart gedeelte (handvat) een dieptezicht te geven.

Aluminium

Hiervoor heb ik aluminium gebruikt van 1 mm dik.

Alu van 0,5 mm is te dun en 2 mm is weer te dik. Zeker voor het plooiwerk. Alu van 1 mm geeft voldoende stevigheid en is nog gemakkelijk zelf te plooien en te buigen.

Als de kartonnen versie voldoet kan deze overgetekend worden op een aluminiumplaat. Het is aan te raden eerst wat ruimer te nemen, dit kan achteraf nog op maat worden afgezaagd want als alles te klein uitvalt is het niet meer te corrigeren.

Na het uitzagen van de vorm, openingen en plooiwerk voor de bevestiging, kan men het aluminium paneel al eens voorlopig bevestigen om te zien of de aansluitingen aan de ‘eyebrow windows’ en zijkant Overhead (bijna) kloppen. Hierbij kan men ook bepalen waar de lijnen moeten komen voor de verschillende plooien in de bovenzijde (indien nodig). Dit om het vormen van vlakke delen waartegen de verschillende opbouwelementen moeten komen.

Plooien en hoeken

Om plooien en hoeken te maken in een aluminiumplaat leg ik deze tussen 2 MDF-panelen zodat de getekende plooilijn gelijk komt met de beide randen van de MDF-panelen. Alles zet ik goed vast met 2 sergeanten.

Vervolgens neem ik een 3de MDF-paneel en ik druk met de platte zijde op het te plooien gedeelte en dit vanaf de rand totdat de plooi voldoende is voor de verkregen hoek.

Opgepast! Een foute plooi is moeilijk of niet weg te werken! Toch niet met ‘huis-en-tuin-gerief’.

Vervolgens is het dan passen en nog eens passen totdat alles op de juiste plaats zit en dit door minder of meer te plooien. Ook door het gebruik van de metaalzaag voor links en rechts wat weg te zagen en voor het fijne werk is de metaalvijl erg nuttig.

Hier heeft de ervaring geleerd dat aluminium aardig scherp kan zijn en dus kleine beschadigingen kan aanbrengen aan de ‘Eyebrow windows’ en Overhead. Opgepast is dus de boodschap.

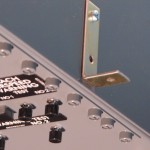

BEVESTIGING

Aan de voorzijde wordt de ‘rear ceiling’ bevestigd tegen de ‘Eyebrow windows’ met 4 bouten van 6 mm.

Aan de Overhead heb ik aan de zijkant een 3-tal L-beugels gemonteerd voor de bevestiging van de karton en later de aluminium. Deze beugels komen +- een 5 mm boven de rand van de overhead.

De bevestiging gebeurt met boutjes van 4 mm.

Aan de achterzijde heb ik een aluminium L-profiel (25 mm x 25 mm) bevestigd dwars tegen het metalen cockpitframe. Eerst heb ik draad getapt in het cockpitframe voor bouten van 6 mm waarmee het aluminiumprofiel wordt bevestigd.

De hoogte van het L-profiel komt gelijk (- 5mm)met de onderzijde van After Overhead.

Aan de onderkant van het aluprofiel wordt dan de ‘rear ceiling’ vastgemaakt met boutjes van 4 mm.

Deze achterkant/onderkant van de ‘rear ceiling’ loopt verder door tegen de binnenzijde van de buitenbenen van het metalen cockpitframe (? – nog eens lezen).

Hier wordt een gedeelte van de ‘rear ceiling’ ingeplooid met dezelfde breedte als de benen van het cockpitframe (50 mm) en vervolgens met plaatschroeven vastgeschroefd tegen het frame.

Langs de buitenzijde wordt de ‘rear ceiling’ vastgemaakt op de bovenkant van de window frames.

Ook weer hier wordt een gedeelte van de aluminium plaat van de ‘rear ceiling’ een 6 cm omgeplooid zodat het omgeplooid gedeelte horizontaal en parallel komt te liggen op de bovenzijde van het window frame.

De bevestiging gebeurt ook met boutjes van 4 mm.

OPBOUWELEMENTEN F/O-ZIJDE

Zoals reeds is vermeld in het begin van dit hoofdstuk zijn de afmetingen van de opbouwelementen ‘onder voorbehoud’ en zijn dus op ‘raming’ gebeurd.

De afstanden tussen de verschillende opbouwelementen heb ik ook geprobeerd om die te laten overeenkomen met de echte versie.

Ik heb opgemerkt dat de setup van de FlyEngravity window frames (met Eyebrow windows) nogal breed uitvallen met het resultaat dat de ‘rear ceiling’ ook breder en groter is. Hierdoor komen sommige opbouwelementen (paneel ‘Emergency Escape Rope’ en paneel verlichting ‘Circuit Brackers’) wat verder van elkaar te liggen.

Deze opbouwelementen zijn uiteraard ‘dummies’ (behalve de speaker en ‘Circuit breakers verlichting’).

Speaker

De ‘speaker’ in de ‘rear ceiling’ is een inbouwluidspreker en komt van Conrad.be.

De inbouwdiameter bedraagt 77 mm. De totale diameter van de volledige luidspreker met rand is 100 mm.

Op de plaats van inbouw heb ik eerst een cirkel getrokken en vervolgens heb ik de omtrek voorzien van kleine gaatjes. Nadien is alles mooi rond gemaakt met een vijl.

Voor de bevestiging van de luidspreker heb ik eerst de 4 gaatjes geboord en nadien draad in de gaatjes getapt. Dit vergemakkelijkt de bevestiging.

De speaker wordt later aangesloten op een mini-versterker die via een Prosim Audiomodule de juiste geluiden zal moeten weergeven.

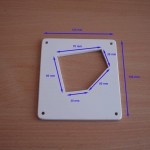

Paneel ‘Circuit breakers’ verlichting

Het paneeltje van de ‘Circuit breakers’ verlichting is gemaakt van PVC Foam board van 6 mm dik.

PVC Foam is zeer licht en men kan het ook een beetje plooien. Dus bij krommingen geeft het dus een beetje mee.

De openingen zijn gemaakt met een figuur- en decoupeerzaag en nadien mooi recht gemaakt met een vijl en schuurpapier.

De hoeken zijn afgerond ook met een vijl en schuurpapier.

De bevestiging gebeurt met 4 boutjes (4 mm x 15 mm) op de 4 hoeken.

Nadien zal in de binnenzijde van deze opening (buitenzijde ‘rear ceiling’) een nisje met lampje worden ingebouwd.

Nis ‘Circuit breakers’ verlichting

Het nisje voor het lampje van de ‘circuit breakers’ -verlichting heb ik gemaakt van een leeg vlootje van de Philadelphia-smeerkaas.

Het is stevig genoeg en zeer licht. Dus gemakkelijk te plakken aan de buitenzijde van de ‘rear ceiling’.

Gewoon een gaatje gemaakt en een lampje (bulb) in een schuine hoek erin gedraaid. Het lampje komt van de Gamma.

Eerst heb ik het lege vlootje aan de binnenzijde geschilderd in dezelfde kleur als de ‘rear ceiling’. De buitenzijde van het vlootje kreeg een zwarte kleur om lichtinval van buitenaf te voorkomen.

Vervolgens heb ik het vlootje met lampje met ducktape bevestigd boven op de opening in de ‘rear ceiling’.

Vermits ik niet beschik over de ‘Circuit breakers’ heb ik het lampje niet aangesloten en dient het dus enkel als ‘dummy’.

Trouwens daarvoor is het kaasvlootje niet geschikt (wordt te warm). Een ledlampje zou wel kunnen.

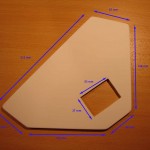

Paneel ‘Emergency Escape Rope’

Idem

De bevestiging gebeurt met dubbelzijdige kleefband. Deze kleefband heb ik gehaald in de Aldi, kleeft heel goed en laat zich evt nadien gemakkelijk verwijderen.

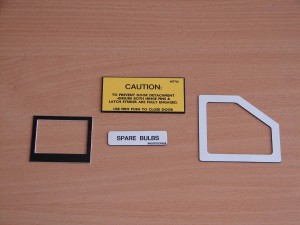

Paneel ‘Spare bulbs’

Idem

De bevestiging gebeurt gedeeltelijk met dubbelzijdige kleefband en met de boutjes van het handvat.

Boven het handvat bevinden zich ook nog 2 boutjes voor de bevestiging. Deze boutjes kan men ook terugvinden bij de echte versie.

De linkse rand loopt parallel met de rand van de ‘Eyebrow Window’.

Air vent rooster (Airco)

De Air vent rooster (grill) is samengesteld uit :

- 1 Bovenplaat van MDF van 25 mm;

- 2 MDF balkjes van 15 mm x 15 mm;

- 6 stukjes van een plastiek hoekprofiel van 15 mm x 15 mm (Gamma of Brico);

- 1 Afgerond driehoek aluminiumplaatje (2 mm dikte);

- 3 verzonken bouten met platte kop (4 mm x 25 mm).

De MDF balkjes van 15 mm worden op de bovenplaat gelijmd met houtlijm. Nadien worden 6 kleine stukjes van het kunststof hoekprofiel (met secondelijm) op de binnenzijde van de bovenplaat gelijmd. Deze kleine stukjes van het hoekprofiel moeten de ribben (vinnen) voorstellen van de ‘Air vent grill’.

Als deze ondersteboven tegen de ‘rear ceiling’ hangt kijkt men enkel tegen de bovenplaat met alu-gedeelte en het begin van de vinnen. Dat is alles wat zichtbaar is en wat we dus enkel moeten zien …

De bevestiging gebeurt met 4 verzonken bouten van 4 mm x 25 mm. Deze boutjes komen op de randen van de MDF-balkjes van 15 mm en bovenplaat en gaan door de aluminium van de ‘rear ceiling’. De vierde bout bevestigt de aluminium driehoek en gaat ook door de aluplaat van de ‘rear ceiling’.

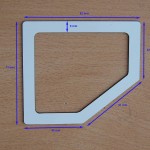

Hierbij een tekening met de afmetingen van de verschillende opbouwelementen van een oudere B737-800-versie. Deze afmetingen zouden voor 95% moeten kloppen (Opm. Deze tekening heb ik gebruikt als algemene leidraad. De afmetingen en vormen komen dus niet volledig overeen met mijn versie).

Thanks to Warren Soeldner for the drawning.

SCHILDERWERKEN

Alle onderdelen heb ik geschilderd met een spuitbus.

Eerst 2 lagen primer en nadien 2 lagen lakverf.

Eerst heb ik het aluminiumgedeelte wat opgeschuurd en dit met schuurpapier met korrel P320 .

Daarna wordt alles ontvet met een ontvettingsproduct. Voor aluminium is dit belangrijk.

De primer die ik heb gebruikt is een universele hechtprimer geschikt voor alle metalen, kunststoffen en is snel drogend. Deze verf is van het merk Südwest – All-Grund (Wit -9110).

De kleur van de lakverf was niet gemakkelijk te bepalen. Op foto’s kan je zien dat het een witte kleur is. Maar deze foto’s zijn meestal genomen met extra belichting (met de flitslamp) en zien er dus helder wit uit.

Bekijk je cockpitfoto’s die genomen zijn bij daglicht en zonder extra belichting is de kleur meer gebroken wit. De test kan je doen door witte onderdelen in de echte cockpit te vergelijken met de kleur van de ‘rear ceiling’. Hieruit blijkt dat het duidelijk gebroken wit is.

Maar in gebroken wit hebben we weer verschillende soorten zoals ‘parelwit’ (RAL1013), ‘cremewit’ (RAL9001), ‘signaalwit’ (RAL9003), ‘zuiver wit’ (RAL9010). De juiste kleur bepalen is dus moeilijk en hangt een beetje af van persoonlijke voorkeur.

In deze verschillende witte kleuren zitten er weinig pigmenten en in een donkere omgeving gaan deze kleuren na een tijdje vergelen. Daarom heb ik de kleur ook wat witter genomen.

Ik heb gekozen voor ‘Verkeerswit’ (RAL 9016) (GN.01.86 – ACC Color Map).

Deze verf is van het merk ‘Sikkens’ – Rubbol Finura Satin (PU zijdeglanslak met geringe donkervergeling).

De luidspreker heb ik ook een schilderbeurt gegeven. De rand is in RAL9016 en het middelste geperforeerde gedeelte in Boeinggrijs.

DECALS EN AFBOORDLIJSTJES

De opening van het paneeltje van de ‘Circuit Breakers’-verlichting heb ik van een extra afboordlijstje voorzien om de omlijningen van de opening beter te laten uitkomen.

Ook op het paneeltje van de de ‘Emergency Escape Rope’ heb ik op de opening een zwart afboordlijstje geplaatst uit kunststof. De achterzijde is dichtgemaakt in diepte en geeft dan het uitzicht van een nisje voor de opening van het (dummie)luikje. Het achterzittend nisje is ook zwart geschilderd en wordt aan de buitenkant van de ‘rear ceiling’ op de opening geplakt met dubbelzijdige kleefband.

Het paneeltje van de ‘Emergency Escape Rope’ is verder voorzien van een sticker met rode tekst.

Hiervoor heb ik het lettertype Tw Cen MT gebruikt en dit met een lettergrootte van 42.

Bij sommige luchtvaartmaatschappijen zien we op dit paneeltje ook een sticker met een de afbeelding van een mannetje dat van een koord klimt. Die hebben we er dan maar ook bijgevoegd.

De sticker heeft een afmeting van 45 mm x 54 mm. Afgedrukt op fotopapier en aan de achterzijde voorzien van dubbelzijdige kleefband. Simpel …

Op het paneel van de ‘Spare Bulbs’ heb ik geen stickers gebruikt maar gegraveerde plaatjes.

Het witte plaatje met ‘SPARE BULBS’ is gemaakt met het lettertype Arial Bold met lettergrootte 17 en 7. Afmetingen van het plaatje : 60 mm x 16 mm.

Het gele plaatje ‘CAUTION’ en ‘INT713’. is gemaakt met het letterype Arial Bold met lettergrootte 22 en 7.

De doorlopende tekst is gemaakt met lettertype Gill Sans MT Bold met lettergrootte 10

Afmetingen van het plaatje : 85 mm x 40 mm.

Deze gele decal is vooral te vinden in de Ryanair-Boeings.

Het zwarte handvatje komt uit de Gamma en is gemaakt uit kunststof.

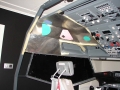

AFWERKING ‘REAR CEILING’ F/O-ZIJDE’

Na de schilderwerken kan de definitieve montage gebeuren.

Eerst het aluminium paneel en nadien de bevestiging van de opbouwelementen. Dit gebeurt met boutjes voor de ‘circuit breaker- en ‘bulb spare’ -paneeltjes. De ‘Air vent’- rooster is ook bevestigd met bouten (4).

Voor de bevestiging van het ‘Emergency Escape Rope’ -paneel en ook voor extra bevestiging van het ‘Bulb Spare’-paneel heb ik dubbelzijdige kleefband gebruikt.

De zijranden aan de ‘overhead’ en randen tegen de buizen van het metalen cockpitframe heb ik netjes afgeboord met afboordstrips.

Dit afboorden met witte strips kan men ook zien in de echte B737-vliegtuigen.

Deze afboordstrips heb ik gehaald in de Aldi en ze dienen om in een badkamer een boordje te maken tussen bad en tegels. Ze zijn heel soepel en plakken goed. Ze zijn trouwens ook te vinden in de Gamma.

F/O ZIJDE

CPT ZIJDE

De ‘rear ceiling’ aan CPT-zijde heb ik volgens hetzelfde concept gemaakt zoals bij F/O-zijde.

Weer het moeilijk plooiwerk en het buigen van de aluminium.

De opbouwelementen zijn :

- Luidspreker;

- Emergency Escape Rope-panel;

- Air vent rooster (Airco);

- Air vent eyeball (Airco).

De ‘Air vent eyeball’ heb ik gemaakt volgens hetzelfde principe als die te vinden zijn in mijn ‘lower panels’ van de MIP.

De nis in de ceiling waarin de ‘eyeball’ komt is gemaakt uit een dekseltje van een plastiek potje waarin kaasblokjes hebben gezeten. Dus eigenlijk gratis en vrij eenvoudig te maken.

Deze nis zou in principe wat meer naar achter moeten komen maar vermits mijn cockpit niet groter is gaat dit dus moeilijk :-).

Alle opbouwelementen, op de luidspreker na, zijn dummies.